Our professional lockout services

ASSESMENT / DIAGNOSIS OF YOUR PRACTICES

Our lockout experts perform a detailed diagnosis to assess the state of the current situation as well as the consistency of your practices between your different sites, if applicable. This diagnostic highlights the good practices already in place and the improvements required. This is done with the aim of ensuring that you comply with laws, standards and good practices in lockout.

The results of this assessment are presented in the form of recommendations. Among other things, it allows you to develop an optimal action plan and a timetable while respecting your capacity for implementation. This evaluation will require you to visit your various sites. Subsequently, a statement of all the necessary elements will be submitted, making it possible to estimate the effort to be made to improve your lockout program.

In short, the diagnosis allows you to know your strengths and weaknesses. It gives you a clear picture of your situation without ambiguity. This is what will allow us to make a concrete action plan that allows you to do due diligence in addition to improving the health and safety culture within the company.

HAZARDOUS ENERGY MANAGEMENT PROGRAM (lockout)

Creating or improving your program

The development of a lockout program for the entire company is the basis of an effective system. This establishes the operating rules and the tools required to comply with the requirements of standards and laws.

A lockout program must contain the following elements:

- The requirements

- Tasks and responsibilities

- Lockout sheet

- Lockout application

- Tools and materials

- Particular situations

- Training

- Audits and inspectionss

Fabtech ID can help you in the development of your program thanks to the expertise of its team which, with more than 35 years of experience in an industrial environment, will offer you innovative and practical solutions that correspond to your concerns and your reality. work.

DEVELOPMENT AND DRAFTING OF LOCKOUT SHEET

The implementation of lockout requires the drafting of clear lockout procedures for each piece of equipment and for each task performed in the dangerous zone of a machine.

Writing accuracy, terminology and the inclusion of reference images when required are important elements when developing detailed energy isolation procedures.

Writing can be done according to the tools you use or according to what we offer you.

We are accredited to use our customers' CONFORMiT® software.

Fabtech ID professionals will analyze each of your equipment / machines / systems to ensure that all hazardous energies are under control in the work area of your employees

In addition, be aware that the process of validation and approval of the sheets is the responsibility of the owner of the equipment. It is therefore essential to involve the competent and experienced staff of the organization to take ownership of these procedures.

*The image is for reference only: our team can provide you with lockout sheets in English.

Training

Training gives your organization the means to create and maintain a safe working environment. A lockout management system requires ongoing training. Fabtech ID offers different types of training to suit your needs..

► Basic training (lockout 101)

This basic training course focuses on the basic principles of lockout/tagout. In addition to reviewing the regulations, laws and standards in force, it presents the various specific situations your workers may be faced with.

► Training of workers (adapted according to the specific program of the client)

This “ custom-made ” training is based specifically on your organization's program. It is reserved for workers authorized to apply lockout. At the end of the training, two evaluations will be carried out, one theoretical and the other practical. A certificate of achievement is issued to participants following training, where applicable.

► Customized in-house trainer training (train the trainer)

To enable you to maintain your workers' skills independently and facilitate the integration of new employees, our professionals offer train-the-trainer courses. This comprehensive training program is specifically tailored to your organization's lockout program. At the end of the training, two evaluations - one theoretical, the other practical - will be carried out. A certificate of completion is issued to participants where applicable..

►

Training in lockout sheet writing

Our lockout experts know all the details and specific requirements of the standards in force. They can therefore assist your in-house team in the preparation of lockout sheets, by training them in the in-depth analysis of the energy sources to be neutralized and in the drafting of your sheets.

Simulation in a controlled environment during training. Fabtech ID has developed two padlocking simulators specially adapted to represent the different energy points to be controlled in your work environment. Your trainers and workers will be able to experiment with the different devices and lockout steps without risking safety.

MATERIAL MANAGEMENT AND SPACE ORGANIZATION

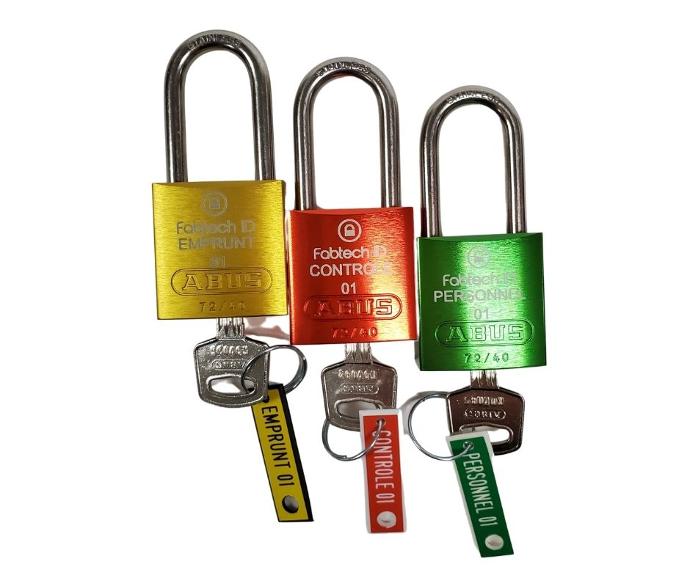

Lockout materials and equipment are essential for an efficient application of lockout and to ensure that all workers have ownership of the system. Our experts can provide advice and recommendations on the right types of padlocks to deploy, key systems, required lockout mechanisms, required identification tags, and the plan for deploying lockout boxes and stations through your facilities..

We offer a complete line of lockout tagout products and solutions bases on the 5S vision to ensure optimization and improve overall productivity.

Our experience of more than 35 years in the field of lockout allows us to confirm that easy and quick access to lockout equipment saves time, improves worker confidence and reduces accidents and the risk of injury.

Access the assessment tool here.

AUDIT AND INSPECTION

This audit validates that your policies and procedures are respected and effective, and ensures that all staff members are involved in continuous improvement.

The results of these audits will be compiled in a simple, comprehensive report to confirm the mastery of acquired skills and provide you with a list of recommendations and corrective actions to include in your annual plans.

Evaluate your lockout system with free online tools

Our Approach

At Fabtech ID, we believe that the risk of accidents related to energy isolation can be eliminated by developing and integrating a hasardous energy control system understood by workers, contractors and management. SIS offers you that peace of mind.

Why choose Fabtech ID?

Performance & Sustainability

For a global and uniform management

•

Uniformity of the lockout at all facilities

•

Compliance with laws and standards

•

Corporate image as a responsible company

• Standardized audits throughout yhe organization

•

One stop shop and cost reduction

For optimization of production activities

•

Operational excellence

•

Compliance with laws and standards

• Reduction of tasks execution time

• Optimal staff training and integration

• Continuous inspection and maintenance of equipment

For increased security at all levels

• Global management of the lockout program

• Creation of an HSE culture and employee trust

• Reduction of accidents and potential injurie

For a system adapted to the reality of your organization

•

Quick access to the equipment needed to work safely

• Reduces risk of injury

• Participation in the continuous improvement of safety

• To facilitate operations on several sites or factories

Want to improve your system?

Don't wait any longer, contact us today!

Write to us and take your business to the next level.

Innovation

We have developped a whole range of products and equipment which allow an optimal use of SIS.

The Safety Innovation Systems are inspired by the 5S model: create and organized workflow, simple.

The system is ADAPTATIVE and SCALABLE. It is adjustable and suited for all environments and can easily be upgraded and modified according to changes.

Failsafe

Our coding devices are an integral part of our lockout solutions. As the name suggests, they help prevent errors during energy isolation activities. Using icons, symbols, shapes and color coding, your workers will know at a glance where each item goes in your lockout boxes or stations, regardless of their language or reading level. It just goes to show how universal our solutions are.

See our products

Take charge of your lockout tagout program today!

Contact us for more information!